Széchenyi 2020 / GINOP-1.2.10-19-2019-00043

| Beneficiary: | FiberOptic Korlátolt Felelősségű Társaság |

| Project ID: | GINOP-1.2.10-19-2019-00043 |

| Project title: | Funding of technological modernization at FiberOptic Kft. |

| Subsidization amount: | 28.01M HUF |

| Subsidization ratio: | 70% |

| Implementation: | 28/02/2021 |

Project details

The main goal and focus of FiberOptic Kft. is to provide cutting edge services and supplying high end products with a competitive price tag to be an attractive option in domestic, EU and overseas markets alike.

As the market evolves, thus becoming more competitive, it is of utmost importance to keep up with new developments in our field by investing in the implementation of cutting edge production equipment and state of the art measurement devices to our passive optical cabling assembly production line, enhancing production efficiency by cutting production costs, increasing first pass yields and reducing dependency on operator skills and experience greatly.

Focusing on development and automation of key processes, FiberOptic Kft. has implemented the following production equipment to their passive cable and component assembly line in the cycle of this project:

PHENIX fibersect.multi mechanical fiber cleaver

Removes excess fiber after the termination process of single and multi-fiber (MPO/MTP) optical connectors by using a mechanical cleaving mechanism, yielding uniform results in a controlled fashion instead of relying on manual labor, automating a high risk and tedious key production step. By providing significantly smaller fiber protrusion with minimal deviation in length, further key production processes may be optimized and streamlined further due to pre-determinable process input parameters.

DOMAILLE ENGINEERING APM-HDC-5300 programmable optical connector polishing machine

Product performance is greatly affected by the quality and geometry of the connector end face which are both regulated by strict standards in both the Europe (IEC) and overseas (TIA) alike. In order to meet and exceed said requirements in an efficient manner, maximizing first pass yields is a key factor which requires the fine-tuning and live monitoring of dozens of parameters during the connector polishing process and that is where the APM-HDC series polishing machines really shine.

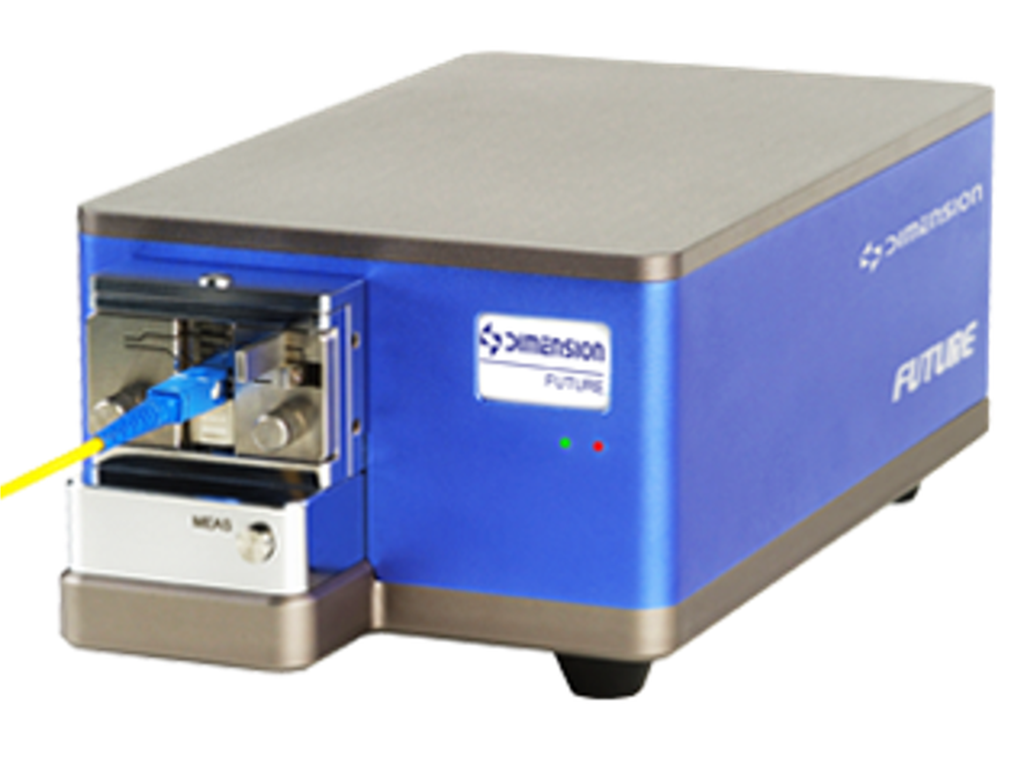

DIMESION FUTURE interferometer

3D scanning and analyzing micro- and nanometer level geometric parameters of the optical connector end face to verify and validate whether the products meet the strict regulations of international standards (IEC, TIA) applicable to passive optical cabling assemblies, storing the date locally or on a dedicated server, ready to generate customized measurement reports on demand.

JGR Optics MS12001 measurement system mainframe

Attenuation and back reflection values define the performance and data transmission capabilities of optical components in an optical network environment, thus the method of analyzing and validating said parameters are strictly pre-defined in tele- and datacom standard worldwide. The MS12001 test system fully accommodates these standards and allows the operator to focus on testing the products thanks to a wide variety of pre-programmable options and setups.

Széchenyi 2020 / GINOP-8.3.5-18/B

| Beneficiary: | FiberOptic Korlátolt Felelősségű Társaság |

| Project ID: | GINOP-8.3.5-18/B |

| Project title: | Working capital loan for operating costs and inventory financing |

| Project details: | Counteracting uncertainties arising in the global supply chain by increasing component stock for high runner key products. |

| Subsidization amount: | 25M HUF |

| Implementation: | 20/09/2022 |

Széchenyi 2020 / GINOP-8.3.5-18/B

| Beneficiary: | FiberOptic Korlátolt Felelősségű Társaság |

| Project ID: | GINOP-8.3.5-18/B |

| Project title: | Working capital loan for operating costs and inventory financing |

| Project details: | Counteracting uncertainties arising in the global supply chain by increasing component stock for high runner key products. |

| Subsidization amount: | 50M HUF |

| Implementation: | 27/12/2022 |